|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

High Precision Induction Pipe Bending Machine For Large Size Steel Tubing

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

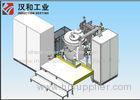

Medium frequency induction pipe bending machine type WGYC-325<s

Medium frequency induction pipe bending machine type WGYC-325

Specification

| Bending diameter | 76-325mm | Feeding speed | 50-60mm/min |

| Bending radius | 2.5-5D | Working power | 500kw |

| Bending angle | 0-180° | Voltage | 380V 50/60Hz 3phase |

| Wall thickness | 8-60mm | Power supply | KPGS-300/1S |

Description

Adopt electron-magnetic induction principal, quicker heating, less burning loss, lower labor strength.

Induction coils adopt whole heterotype copper pipe winding, tidy and beauty, precise sizes, high mechanical strength, high electrical efficiency.

After loading the pipe the pusher moves with the grip head along the pipe until it ends at the stop plate. The pipe will be hydraulic clamped.

When the pipe is hydraulic clamped, the feeding movement will take place.

The induction system consists of high current transformer, static thyristor exchanger, medium frequency transformer, operation panel, and inductors and their adjustment.

The process can be recorded and stored in the hard disk, and the data can be directly printed. Words input is accepted.

The bending radii basically depends on the pipe diameter, wall thickness and material properties.

Principle

This complete set of medium frequency induction heating pipe bending machine adopts electron magnetic theory which can converts the 3 phase power frequency into single phase middle frequency power energy. The work-piece is been put into the circumanstance of vacuum and protective gas, and the alternating magnetic field will generate eddy-current loss and produce huge heat, thus it can meet the heating requirement of smelting, diathermanous, quenching and bending.

Application

This complete set of induction heating pipe bending machine is widely used in:

Petrochemical

Power generation

Chemical

Oil and gas

Ship building

Construction

Areospace

Competitive Advantage

Large memory can store various groups of technology.

Cost efficiency. Straight material is less costly than standard components (e.g. elbows) and bends can be produced faster than standard components can be welded.

Elbows can often be replaced by larger radius bends, reducing friction, wear and required pump capacity.

Induction bending reduces the number of welds in a system.Induction bends are stronger than elbows with uniform wall thickness

No welds at the critical points thanks to the tangents.

Even heating temperature makes bending effect consistently.

Stock of elbows and standard bends can be greatly reduced.

Bends can be made from the same base material as the straight pipe.

Detailes Image

Advanced pipe bending technology for your choice!

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)