|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

Diathermanous Induction Heating Furnace For Carbon Steel Pipe

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Cost effective induct

Cost effective induction middle frequency diathermanous furnace

Specification:

Technical parameters for reference:

|

Pipe diameter(mm)

|

Power(kw)

|

Frequency(khz)

|

Temperature()

|

Heating efficiency(kg/h)

|

Electric Power Consumption (kw/h) |

| 5-12 | 50 | 10-40 | 200-1250 | 138 | 360 |

| 5-30 | 100 | 4-40 | 200-1250 | 278 | 360 |

| 12-40 | 160 | 4-20 | 200-1250 | 445 | 360 |

| 30-80 | 250 | 1-4 | 200-1250 | 698 | 360 |

| 50-100 | 500 | 0.5-2.5 | 200-1250 | 1388 | 360 |

| 80-100 | 1000 | 0.5-1 | 200-1250 | 2778 | 360 |

| 120-160 | 1000 | 0.2-0.5 | 200-1250 | 2778 | 360 |

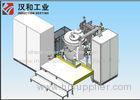

The complete set of inductin heating furnace is made of middle frequency power supply, capacitance transformer cabinet, induction heating coil, water cooling connecting cable, supporting lining, furnace body fixture.

Description:

The complete set of induction heating furnace takes advantage of electromagnetic induction heating theory which can converts the 3phases power frequency electricity into single phase electricity which can generate great heat for preheating the steel pipes.

The whole system adopts full digital control which can realize power factor calibration, constant power control, temperature control, frequency tracking, zero power start-up, real-time monitor on over-current and over-voltage faults, alarm display etc.

The induction heating furnace adopts unique zero voltage, sweep frequency, soft start-up mode, users can leisurely select one-time start-up or automatic repeatable start-up mode.

Complete and reliable protection system on over current, over voltage, low voltage etc.

The central control panel adopts single-panel structure, highly integrated, 3 phases synchronous, rectification trigger and control, inversion trigger and control, the rectification pulse transformer unit is mounted on a central control panel which is of high interchangeability and convenient for user maintenance and change.

The lining can be categorized into the following types: white corundum, stainless steel and integral sintered, which can be selected by users themselves.

The equipment has a complete and reliable automatic adjustment system made up of current, voltage, impedance and inverter leading trigger angle adjustments. The current and voltage double circles automatically achieve constant power adjustment, the impedance adjustment can make the power supply be the optimum state during the whole smelting process.

Competitive advantage:

Electricity is a kind of clean energy which has little pollution and harm to the environment.

High speed of heating.

Provide computer integrated monitoring system and realize the intelligent management and production.

The induction power supply can be used for different sizes of steel pipes.

Less oxidation and decarbonization.

Less energy consumption.

High degree of automation.

The equipment can achieve fully unmanned operation.

Homogeneous heating.

Quick IGBT driver which can improve the shapes of resonant waves, reduce the time of dead zone and decrease the loss of switch as well as increase the stability of the high frequency tracking converter.

It provides the pneumatic/ hydraulic push step-by-step and roller continuous conveying artifacts way.

Engineers are available abroad for installation, debugging as well as training.

24-hour technical hotline for your service.

Detailed image:

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)