|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

High Temperature Graphitization Furnace For Graphitizing Treatment

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

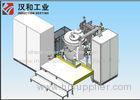

High temperature graphitization furnace for graphitizing treatment

<s

High temperature graphitization furnace for graphitizing treatment

Specification:

| Product Name | Induction melting furnace | Application | Graphitizing treatment |

| Model | THL-200 | Standard | ISO 9001:2000 |

| Rated temperature | 2800 | Rated power | 60KW |

| Rated frequency | 4000Hz | Limiting vacuum | 6.67×10-1 Pa |

| Capacity | 150KG | Material density | 880kg/m³ |

Parameters for middle frequency power supply:

| Middle frequency power supply | Type | KGPS-400/2.5S |

| Input voltage | 3N-380V, 50/60Hz | |

| Output power | 400KW | |

| Frequency of output | 2.5KHz | |

| DC Voltage | 520V | |

| DC Current | 800A | |

| Output voltage | 800V | |

| Rated heating temperature | 2800 | |

| Cooling water flow | 12T/h |

Range of supply:

| Scope of supply | Middle frequency power supply |

| Capacitor chamber | |

| High vacuum pump unit | |

| Induction coil | |

| Electric control cabinet | |

| Connecting cable | |

| Temperature measurement system | |

| Temperature controller | |

| Heat resistance furnace |

Description:

Adopt electron-magnetic induction principal, quicker heating, less burning loss, lower labor strength, better good quality.

The whole system adopts full digital control which can realize power factor calibration, constant power control, temperature control, frequency tracking, zero power start-up, real-time monitor on over-current and over-voltage faults, alarm display etc.

Quick IGBT drive circuit which can significantly improve the wave of the resonance, reduce the time of dead zone and decrease the loss of switch.

Adopts unique zero voltage, sweep frequency, soft start-up mode, users can leisurely select one-time start-up or automatic repeatable start-up mode.

The equipment has a complete and reliable automatic adjustment system made up of current, voltage, impedance and inverter leading trigger angle adjustments. The current and voltage double circles automatically achieve constant power adjustment, the impedance adjustment can make the power supply be the optimum state during the whole smelting process.

Complete and reliable protection system on over current, over voltage, low voltage etc.

Competitive advantage:

3000 ultra temperature, temperature uniformity is ≤10.

Temperature precision is 0.3%, the temperature controlling is ±1.

The vacuum limitation can be set according to technology requirement.

Siemens PLC computer monitor which can improve reliable protection.

Excellent heat resistant material which can improve use-life time.

One power supply two furnace or one power supply four furnace allocations for your choice.

Detailed image:

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)