|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

Hydraulic Pipe Bending Machine For Steel

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Hydrualic pipe bending machine for steel construction/CNC pipe bender<

Hydrualic pipe bending machine for steel construction/CNC pipe bender

Specification

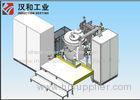

| Product name | Pipe bender | Bending wall thickness | 7-60mm |

| Model | WGYC-530 | Bending angle | 0-180° |

| Bending radius | 2.5-5D | Pipe material | Stainless steel, cast steel, alloy steel |

| Bending diameter | 159-530mm | Feeding speed | 10-100mm/min |

Range of supply:

Middle frequency power supply

Capacitance transformer tank

Supporting connected cables

Induction heating coils

Hydraulic pushing pipe machine

Bending arm

Electrical operation platform

Supporting clamps

Industrial computer

Control software

Closed cooling device

Description

Conditions for middle frequency power supply:

- The sea level height: 3000m

- Environment temperature: -2≤T≤40

- Air relative humidity:≤80%

- Installed room should be well ventilated,with no conductive dust and without corrosive gases

- The place is without violent vibration and impact and explosion hazard

- Cooling water is 1-2mg/cm2, 7PH8, Device shall not be used under the condition of condensation.

Voltage should be a sine wave, Harmonic distortion is less than 5%, Input is three-phase AC, line voltage 380v, Continuous voltage fluctuation range is not more than ±10%, The frequency of the power grid voltage change is not more than ±2% (That should be between 49 to 51 hz), And three-phase voltage unbalance degree should be less than±5%.

The selection of Medium-frequency power supply main circuit thyristor rectifier left sufficient margin, As equivalent to the conventional power 1.2- 1.3 times that of the same capacity selection thyristor, making the overload capacity and reliability has a significant improvement.

Rectifier control uses a new generation of full digital trigger technique. Three-phase synchronous signal is directly introduced from Photoelectric isolation device of 2500v main return path into control panel and realizes automatically balance of strict industrial frequency three-phase current.

Perfect and reliable automatic adjustment system which consists of current, voltage, resistance, four of the inverter triggering before angle regulator, current and voltage automatically realize the constant power regulation, impedance controller can make the power supply and load in the smelting process which is always in a state of optimal operation.

The central control panel adopts single board structure, which is of high level of integration, three-phase synchronous, rectifier trigger and control, inverter trigger and control, regulation and protection, pulse rectifier transformer assembled on the same piece of the central control panel with strong interchangeability and convenient change.

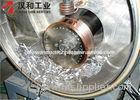

Principle

This complete set of middle frequency induction heating pipe bending machine adopts electron magnetic theory which can converts the 3 phase power frequency into single phase middle frequency power energy. The work-piece is put into the circumanstance of vacuum and protective gas, and the alternating magnetic field will generate eddy-current loss and produce huge heat, thus it can meet the heating requirement of smelting, diathermanous, quenching and bending.

Application

The pipe bending machine is widely applied in many industrial fields:

Areospace

Oil and gas

Steel construction

Boiler

Ship-building

The pipe bending machine can be used for round, square steel pipes as well as joist.

Competitive Advantage

Large-tonnage hydraulic or chain type mechanical pipe pushing, stable pipe bending process.

Adjustable bending arm adapts to different radius adjustment.

Siemens PLC programmable control on radius adjustment, bending angle, speed of bending, heating temperature and cooling water control.

PLC industrial computer used for integrated monitor of technological parameters of the bent pipe to ensure the consistency of the bending.

Large memory can store various groups of technology.

Mature and advanced pipe bending technology for years.

Stable running during the whole processing period.

Whole special copper tube winding induction heating coil which is in compact design, precise dimension, high mechanical strength as well as electricity effeciency.

Hydraulic power station and high-pressure oil pipe are strictly manufactured with pickling passivation treatment according to international standard.

Complete and safe protection for over voltage and over current and other faults.

IGBT (SIEMENS) technology, high conversion efficiency; Energy saving 15%-30% ,compared to SCR/KGPS technology.

24 hours technical survice hotline for you.

Engineers are available to abroad for equipment installation, debugging as well as training.

Detailes Image

Advanced pipe bending technology for your choice!

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)