|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

Heat Treatment Induction Hardening Machine With Siemens PLC Control

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

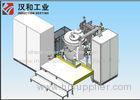

Siemens PLC control system induction vertical

Siemens PLC control system induction vertical quenching machine

Specification:

The equipment takes advantage of middle frequency power supply with quenching lathe. The heating power supply uses the most advanced frequency conversion device which can converts the 50HZ 3phase power frequency electricity into single phase middle frequency electricity.

The scope is supply is as following:

Transistor tube high frequency power supply

Capacitance transformer cabinet

High efficiency quenching transformer

Rolling quenching special machine

Induction heating coil

Automatic feeding/charging device

Charging box

Discharging device

Electrical control system

CNC system

Description:

The power supply uses full-bridge inverter, current DC/DC voltage adjustment, and series resonance. The most advanced DSP digital transistor tube high frequency control circuit is applied to ensure the transistor tube will always work under ZCS condition no matter how the loading varies.

Rectifier control uses a new generation of full digital trigger technique.

The central control panel adopts single board structure, High level of integration, Three-phase synchronous, rectifier trigger and control, Inverter trigger and control,regulation and protection, pulse rectifier transformer assembled on the same piece of the central control panel with strong interchangeability and convenient changing.

Inverter starting adopts unique zero pressure, frequency sweep, soft starting, The user can select a start or repeated start boot mode, launch control link searches automatically real time natural oscillation frequency load, to ensure that whatever light load, heavy, cold, hot,success start rate is 100%.

The electrical capacitance transformer cabinet uses world leading non-polar thin film capacitor. The isolation transformer uses mirco crystal material for high frequency coupling transformer which is used for the energy conversion.

The connecting electrode uses water cool connecting electrode, safe and reliable operation. The raw material is red copper.

Technological parameters for quenching and tempering of various parts and components can be stored and furthermore adjusted and selected randomly.

Application:

It is used to the quenching of fittings such as shafts and gears.

Competitive advantage:

Automatic charging and discharging method, easy operation.

Perfect and reliable automatic adjustment system which consists of current, voltage, resistance, four of the inverter triggering before angle regulator, current and voltage automatically realize the constant power regulation, impedance controller can make the power supply and load in the smelting process which is always in a state of optimal matching.

Selectable single and double station structure.

Siemens PLC programmable control system is used to control various parameters.

Fixed induction heating coil and work-piece rotating movement for quenching and annealing.

World leading technology and intelligent control ensure uniformity in quenching thickness.

Potential isolation, safe and reliable operation. Easy and simple match. Convenient adjustment. Wide scale of loading.

The rotating speed can be adjusted, and the rotating angle can be positioned control.

Highly efficient and stable induction heating system.

Intelligent and highly stable numerical control system and driver.

The heating temperature under precise monitoring and controlling.

Engineers are available abroad for installation, debugging and training.

Detailed image

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)