|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

3D Rapid Prototyping Industrial Metal Powders With High Corrosion Resistance Property

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

3D rapid prototyping powders used in areospace and bioc

3D rapid prototyping powders used in areospace and biochemical industry , special metal powder

Specification

With the development of science and technology, 3d rapid prototyping improves dramatically. TC4, 316L as well as other metal powders are in great demand.

TC4

Ti (balance)

Al (5.5 - 6.75 wt-%)

V (3.5 - 4.5 wt-%)

O (< 1600 ppm)

N ( < 500 ppm)

H ( < 150 ppm)

Fe ( < 3000 ppm)

Density 4.40g/cm³

Particle size -250mesh

Powder particle specific surface area 0.1910m/g

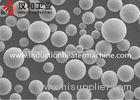

Degree of sphericity ≥97%

Recommended layer thickness 30, 40 um

Apparant density 59.3%

Relative density of formed parts Approx. 100%

316L

Fe (balance)

Cr (17.2- 18.5wt-%)

Ni (11- 14 wt-%)

Mo ( 2-3wt-%)

Si ( < 1 wt-%)

Mn ( < 1.5 wt-%)

Cu ( < 0.5 wt-%)

O (800ppm)

Density 7.93g/cm³

Particle size -270mesh

Powder particle specific surface area 0.102cm²/g

Degree of sphericity ≥94%

Recommended layer thickness 20,30,40um

Apparant density 61.0%

Relative density of formed part Approx.100%

In718

Fe (balance)

Cr ( 17.20-21.0 wt-%)

Ni ( 50-55 wt-%)

Mo ( 2.8-3.3wt-%)

Ti ( 0.65-1.15 wt-%)

Al ( 0.2-0.8 wt-%)

Co ( ≤ 1 wt-%)

Cu ( ≤ 0.3 wt-%)

C ( ≤0.08 wt-%)

Si, Mn (each ≤ 0.35 wt-%)

P, S (each< 0.015 wt-%)

O (< 700ppm)

Density: 8.15 g/cm³

Particle size: -250mesh

Powder particle specific surface area: 0.11cm²/g

Degree of sphericity: ≥96%

Recommened layer thickness: 20,30,40um

Apparant density: 55%

Relative density of formed parts: approx.100%

AlSi10Mg

Al (balance)

Si (9.0 – 11.0 wt-%)

Fe (≤0.55 wt-%)

Cu (≤0.05 wt-%)

Mn (≤0.45 wt-%)

Mg (0.02 - 0.45 wt-%)

Ni (≤0.05 wt-%)

Zn (≤0.05 wt-%)

Ti (≤0.15 wt-%)

P, S (each≤0.01 wt-%)

Competitive advantage

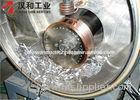

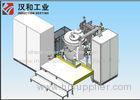

We adopt our mature and advanced vacuum gas atomization equipment for the mass production of the metal powders.

Oxygen content can be controlled to about 700-800ppm.

The shape of the powder is spherical with less satellite.

High errosion resistance property.

Optimal heat resistance

Detailed image

Advanced and mature vacuum gas atomization technology.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)