|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

High Frequency Braze Welding Equipment Compound Pot Bottom Valve

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

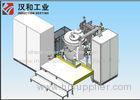

Compound pot bottom valve high frequency braze welding equipment

<spa

Compound pot bottom valve high frequency braze welding equipment

Specification:

This complete equipment is used for high-end stainless steel compound metal pot automatic heating braze welding. The equipment adopts double stations rotating working platform together with intelligent GGP vacuum tube high frequency induction heating system to weld on stainless steel-aluminum-stainless steel compound metal.

The equipment has advantages of quick heating speed, temperature uniformity, long-term stable running as well as easy maintenance.

| Product name | Braze welding device | Heating temperature | 800 |

| Max pot diameter | 400mm | Heating method | One heating |

| Max pot height | 380mm | Working station | Double station |

| Power | 150KW | Input voltage | 380V, 3N |

| Rated frequency | 350KHZ | Input power capacity | 150KVA |

Technical parameters:

| Model | GGPS-1500/350S |

| Input voltage | 3N-380V,50Hz/60Hz |

| Output power | 150KW |

| Output frequency | 300-350KHZ |

| Positive pole voltage | 13000V |

| Positive pole current | 18 A |

| Output voltage | 8000V |

| Heating temperature | 850 |

| Cooling water flow | 20T/h |

Description:

This equipment is of strong technology with high degree of automatic, easy operation, good quality of workpiece welding.

Take advantage of induction heating which is of quick heating, little burning loss and high labor strength.

Proper choice on welding material and brazing flux, which makes the welding quality better.

The infrared thermometer control system non-contact measurement on work-piece. And the control on the middle frequency power supply for the output power adjustment, thus making the temperature on the work-piece constant. The temperature control precision of the welding work-piece can be ± 2%.

The output power of the power supply does not vary when the induction coils and work-pieces change.

All-digital control system, no relay control.

The welding machine adopts fully closed structure design which can avoid the danger of high pressure electricity.

Closed cooling water tower with stable running property requires less energy consumption.

Competetive advantage:

The braze welding device adopts proper transistor tube induction heating power supply, high heating efficiency, good welding quality.

The welding is suitable for whole braze welding and segment welding which can meet the requirement of silver-based and copper-based braze welding material.

The welding strength and electricity conductivity all meet the requirement of technology.

Complete protection function on over-voltage, over-current, phase loss, low voltage, low pressure of cooling water, over-high temperature of cooling water etc.

Full digital control system for precise and real-time monitor and control.

The power supply has following functions: automatic sweep frequency, constant power output, automatic fault display, record and storage of technology data. All these functions can ensure the workpiece is in constant power when it is welded.

Global leading welding procedure is adopted to solve many problems regarding the welding for the users.

World-leading welding technology support can decrease many users’ welding problems.

Engineers are available abroad for installation, debugging, maintenance as well as training.

24-hour technical hotline for your service.

Detailed image:

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)