|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

CNC Metal Bending Tube Induction Pipe Bending Machine Over - Voltage Protection

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

steel pipe bending machine , Pipe bending machin

steel pipe bending machine , Pipe bending machine for stainless steel/alloy steel/cast steel pipes

Specification

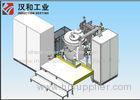

| Model | WGYC-530 | Wall thickness | 8-60mm |

| Bending diameter | 159-529mm | Speed of quick return | 2m/min |

| Bending radius | 2.5-5D | Max thrust | 100T |

| Bending angle | 0-90 degree | Max. stroke | 8m |

Description

-

Rectification control adopts newly all digital trigger technology, high loading capacity and reliability.

-

Complete protection functions for over-current protection, over-voltage protection, controlling power supply low voltage protection etc.

-

Induction coils adopt whole heterotype copper pipe winding, tidy and beauty, precise sizes, high mechanical strength, high electrical efficiency.

-

Hydraulic station adopts well-known variable displacement piston pump. Flow control adopts high precision converter for low flow automatic control.

-

Computer control system uses industrial computer control system.

-

Closed cooling water tower needs less space and can be moved and put according to requirements.

-

Perfect and complete protection functions, increasing machines' reliability and stability.

Principle

After the steel pipe is placed in the proper position, the user shall adjust the bending radius via the screw and nut mechanism which is fixed on the bending arm slewing unit. Then, use the mid-frequency induction system to heat the pipe, after which the pipe is bent. The pipe bending equipment makes use of hydraulic force for pipe bending, and uses a trolley for pipe propelling. After the heated pipe passes through and comes out from the preset runway, it will be cooled down by the water spraying from the circulating water tank. Thus, a bent pipe is created.

Application

This complete induction heating pipe bending machine can be used for the heat induction of various types of round, square or H-shaped pipes, materials for the pipes can be stainless steel, cast steel, and alloy steel. Those pipes are widely applied in petroleum, gas, metallurgy, steel construction and boiler industries, power transmission, urban construction etc.

Competitive Advantage

-

Large-tonnage hydraulic or chain type mechanical pipe pushing, stable pipe bending process.

-

Adjustable bending arm adapts to different radius adjustment.

-

Siemens PLC programmable control on radius adjustment, bending angle, speed of bending, heating temperature and cooling water control.

-

PLC industrial computer used for integrated monitor of technological parameters of the bent pipe to ensure the consistency of the bending.

-

Large memory can store various groups of technology.

-

Cost efficiency. Straight material is less costly than standard components (e.g. elbows) and bends can be produced faster than standard components can be welded.

-

Stable running during the whole processing period.

-

Hydraulic power station and high-pressure oil pipe are strictly manufactured with pickling passivation treatment according to National Standard.

Detailes Image

Advanced pipe bending technology for your choice!

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)