|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

Spherical Powders Gas Atomization Equipment With Atomizing Technology

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

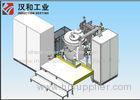

Vacuum gas atomization equipment for spherical powders with atomizing technology

<span st

Vacuum gas atomization equipment for spherical powders with atomizing technology

Specifications:

| Model | VIGA-100 | Nominal power | 160kw |

| Smelting material | Titanium, Aluminum, Stainless steel | Max smelting temperature | 1750 |

| Nominal capacity | 100kg | Working pressure | 2-15Mpa |

| Control method | PLC | Operation interface | Touch screen |

Description:

The vacuum smelting chamber adopts two-layers cold water structure. The outer is A3 carbon steel, and the inner is stainless steel. The furnace is of vertical type and side door can be opened horizontally.

Induction melting furnace is a multi-functional furnace consisting of furnace body, furnace lid, lifting mechanism, inductive coil and furnace tilting mechanism.

Holding furnace/Heat preservation furnace: It's mounted on the nozzle system, it is a holder for the metal liquid and has the function of heat maintenance.

Atomization system is made up of nozzle, high-pressure pipeline, and valves etc.

Atomization cabinet is a container that can connect all devices. It's for the metal droplet solidification. It's combined with stainless steel inner wall, cast steel outer wall, and cooling-water interlayer.

Hydraulic system: A device for increasing hydraulic pressure of tilting furnace and furnace lid.

Air supply system:It's a device supplying air for atomization nozzle. It consists of valves, high-pressure pipeline and air supply bus-bar.

The induction coil is connected to the middle frequency induction power supply out of the vacuum chamber by water cooling electrode.

The vacuum atomizing chamber is made up of high quality stainless steel. The cooling area is 14000 in diameter, 4000mm in straight height. The top and bottom is in taper shape. The bottom is connected to the cyclone separator.

Pump system uses the secondary pump system, the Roots pump uses ZJP-2500, the backing pump uses two H-150. Vacuum valve uses manual butterfly valve.

Cyclone separator adopts the general formula design, lined with high temperature heat insulation material interfaces at the bottom with the atomizing chamber are set the cooling water jacket to ensure the seals for long time using.

Air-flushing control cabinet integrates 40 steel bottles of high purity Argon, by the air flushing high pressure valve and flow control to satisfy technology of production of different granularity of pressure and flow control.

Powder collecting cabinet / power collector is made of stainless steel, in taper structure with small entrance and big bottom.

Heating power supply control mode can be both automatic and manual.

Closed cooling water tower needs less space and can be moved and put according to requirements. Less energy consumption, easy and reliable operation.

Tundish heat resistance heating system is set for increasing the flowability.

The control system is the core component which can deliver all the operations and relative data to PLC, then the results will be shown after operation treatment.

The smelting system is made up of furnace shell, induction coil, feeding temperature monitoring device, watching windows, furnace tilting mechanism, tundish etc.

Principle and application:

The metals to be smelt are put into the smelting furnace from the bottom of the melting chamber, and the metals will be smelt into liquids under the proper protective gas such as Argon or Nitrogen. Then the liquid metals flow down through the induction furnace bottom to the atomization chamber. The liquids will be atomized and solified into small particles during falling down. Then the solid fine powders are created. The fine powders will be collected to the powder collecting cabinet.

The atomized metal powders are widely used in additive manufacturing, 3D printing, thermal spraying, magnetic material, brazing, cemented carbide and diamond alloy tool etc.

Competitive Advantage:

-

The finished product can meet the technical requirement: highly spherical in shape, high purity, low oxygen content, quick speed of solidification, batch-to-batch consistency as well as high degree of cleaniness.

-

We have 24-hour hotline for technical service.

-

Independent research and development guarantee quality, independent design and production guarantee on-time delivery.

-

A team of doctors and professors are always improving the technology and make innovations to serve customers with the most mature and advanced equipment and technology.

-

Adopt secondary classifer and grader which is more environmental-friendly.

-

Cyclone separator adopts winding plate structure which can ensure the long-time use of the sealed parts.

-

There is bufferfly valve and filter device for the pipeline which meets the requirement of environment protection.

Detailed Image:

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)