|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

Gold Index: 7069

Horizontal High Temperature Sintering Furnace With Less Energy Consumption

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

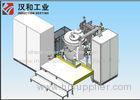

Horizontal protective gas controlled induction sintering furnace

<stron

Horizontal protective gas controlled induction sintering furnace

Specification:

Basic Parameters:

| Product Name | Vacuum induction sintering furnace | Application | vacuum induction sintering |

| Model | ZVF-200 | Standard | ISO 9001:2000 |

| Processing material | Silicon carbide | Effective heating zone | 450(diameter)*900(height) |

| Capacity | 2000kg/batch | Rated heating power | 300kw |

| Operating temperature | max. 1750 | Input voltage | 3N 380V 50Hz |

Supply range:

| Scope of supply | IGBT Middle frequency power supply | |

| Sintering furnace | ||

| Heating chamber | ||

| Vacuum system | ||

| Degumming system | ||

| Inflation system | ||

| Closed cooling water tower | ||

| Compressed air system | ||

| Operation and control system | ||

| Charging carriage | ||

Models for reference:

| Model |

Rated power |

Heating area size (diameter*height) |

Working temperature |

Limit vacuum |

Pressure rise rate |

Frequency |

| ZVF-50 | 60 | 150×200 | 3000 | 4.7×10(-3) | 0.15 | 8 |

| ZVF-100 | 100 | 250×400 | 3000 | 4.7×10(-3) | 0.15 | 6 |

| ZVF-160 | 160 | 360×750 | 2800 | 4.7×10(-3) | 0.15 | 4 |

| ZVF-200 | 200 | 450×900 | 2800 | 4.7×10(-3) | 0.15 | 4 |

| ZVF-300 | 300 | 600×1200 | 2500 | 4.7×10(-3) | 0.15 | 4 |

| ZVF-400 | 400 | 680×1200 | 2500 | 4.7×10(-3) | 0.15 | 2.5 |

| ZVF-500 | 500 | 800×1500 | 2500 | 4.7×10(-3) | 0.15 | 2.5 |

| ZVF-600 | 600 | 600×2500 | 2500 | 5×10(-3) | 0.15 | 2.5 |

| ZVF-630 | 600 | 850×2600 | 2500 | 5×10(-3) | 0.15 | 2.5 |

Description:

Vacuum furnace is in square shape with double steel bar dense welding. The interlay has cooling water baffle plate which can ensure the cooling water evenly cool down each part of the furnace body. The electrode adopts end face seal which has high temperature seal property and good stability.

Method of temperature control: Closed circle PID programmable curve automatic temperature control.

Degree of uniformity: no more than ±5 .

Working process: degumming-sintering-cooling in continuous pattern.

Heating chamber: the insulation heating screen adopts overall composite carbon fiber construction, good insulation effect, less heat loss, easy maintenance and installation.

The heating parts consist of special graphite electrode and optimum heating graphite which can be used for a long time without fraction and easy change.

The inside furnace supporting adopts high strength graphite, with high temperature strength and large load capacity.

Vacuum system: consists of slide valve pump, roots pump, high vacuum oil diffusion pump, filtration device and pipe valve. The system adopts redundancy selection which can quickly realise vacuum.

The diffusion pump has a oil temperature monitoring system which can make the operation more expressive.

The simulation display screen which make the operation easy and visual.

Applications:

The high temperature vacuum induction sintering furnace is mainly for copper-tungsten, Al-Ni-Co Permanent Magnet, NdFeB, carbon fabric graphitization, C/C composite material, silicon carbide products, tungsten- molybdenum and other alloy vacuum or atmosphere high temperature sintering. It can also be used for the heat treatment and vapour deposition for other metallic materials.

Competitive Advantage:

Adopt proper vacuum pump unit which can meet the technology requirement of the vacuum sintering.

Adopt intelligent temperature control meter which can easily set the temperature rising curve. The temperature control precision is high and the temperature can automatically rise according to the program.

Adopt highly efficient middle frequency power supply and induction coil. Large output power and quick speed of temperature rising.

The atmosphere in the furnace is controllable, and the temperature is even. The inside furnace can be injected hydrogen, Nitrogen and Argon etc.

Vacuum sintering can reduce the harmful components of the atmosphere( such as water, oxygen, nitrogen and other impure content) to pollute the materials, thus it can avoid the situations of decarbonization, carburization, reduction, oxidization as well as nitridation.

Detailed Image:

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Zhuzhou Hanhe Industrial Equipment Co.,Ltd [China (Mainland)]

Business Type:Manufacturer

City: Zhuzhou

Province/State: Hunan

Country/Region: China (Mainland)