|

Zhuzhou Hanhe Industrial Equipment Co.,Ltd

|

High Temperature Induction Gas Atomization Equipment For Highly Spherical Metallic Powder

| Place of Origin: | Hunan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

High temperature indu

High temperature induction vacuum gas atomization equipment for powder

Specifications:

Zhuzhou Hanhe are always striving the survival by the quality, striving for the eternal by the prestige, striving for the development by the innovation.

We have many years' experience in induction heating equipment especially for vacuum gas atomization equipment. And our products are popular and recognized among customers home and abroad.

Description:

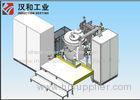

This complete set of gas atomization equipment is for making spherical metal powders under proper conditions such as in vacuum or under the protection of inert gas such as Argon and Nitrogen.

| Vacuum smelting furnace | Double layer water cooling structure design. A3 carbon steel for outer part, optimal stainless steel for inner part. |

| Vacuum atomization furnace | Made of optimal stainless steel. |

| Vacuum pump unit | Adopt secondary vacuum pump unit. The roots pump uses ZJP-500. The vacuum valve adopts hand butterfly valve. |

| Cyclone separator | The inner lining adopts high temperature heat insulation material. |

| Powder collector | Made of stainless steel, in taper structure. |

| Pulse bag dust filter | Locellus off-blast pulse blowing and deashing technology. Strong deashing capability, high effecient dust removement, low rate of air leaking, less energy comsumption, less space occupied, stable and reliable operation. |

| Classier/grader | Adopt Nitrogen closed circuit method. 4 kinds of specifications of powders can be made at the same time, the particle sizes can be adjusted accordingly. |

| Cooling water tower | Circulating cooling water in closed space without impurity. Less space occupied and can be put and moved according to user's requirement. Less energy consumption, easy and reliable operation. |

The whole equipment is made up of vacuum induction smelting furnace, vacuum heat insulation furnace, vacuum pump system, atomization system, atomization cabinet, powder collecting system, gas spply system, water cooling system, control system, middle frequency power supply, operation platform etc.

Principle & application:

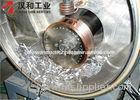

The vacuum induction gas atomization equipment adopts middle frequency induction smelting technology along with vacuum atomization technology. The metal is put into the smelting chamber, the metals will be smelt into liquid metal under protective gas such as Argon or Nitrigen. The liquid metals flow down the bottom induction smelting furnace and through the nozzle. The liquid metals will be atomized and cracked into fine particles by the high pressure gas flow via the nozzle. The liquid metals will be atomized and then cooled and solidified in the atomization chamber during falling down.

Those fine metal powers are widely used in many industrial fileds such as manufacturing additive, laser sintering, laser smelting, electro beam smelting and other industrial equipment spare parts etc.

Competitive Advantage:

The equipment can produce most metal and alloy powders which can not be finished via water atomization technology.

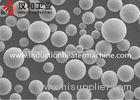

The equipment can make highly spherical or semi-spherical powders.

The particle sizes can be adjusted according to user's special requirement.

Quick speed of solidification.

Low oxygen content.

Batch to batch consistency.

High purity with less satellite.

Engineers are available to service abroad for technical installation, debugging as well as training.

24-hour after sales service hotline for any problems.

Independent nozzle technology which ensures the performance of the atomized powders.

Detailed Image: